MANUFACTURING AND MATERIAL SUPPLY

1. Needs Analysis and Planning

Identifying Needs: Customer demands and project-specific technical requirements are determined.

Technical Specification Preparation: The technical specifications of the products to be manufactured, material types, and other requirements are detailed.

2. Design and Prototype Development

Design: The designs for the products to be manufactured are created by engineering teams. CAD software and other engineering tools are used in this phase.

Prototype Production: Prototypes are produced to verify the design and test its functionality. Prototypes are used to identify design flaws and make necessary adjustments.

3. Material Procurement

Material Selection: The materials required for the production of the products are selected. This may include various materials such as steel, aluminum, plastic, and electronic components.

Supplier Selection and Management: Cooperation is established with reliable suppliers. The quality, costs, and delivery times of suppliers are evaluated.

Ordering and Delivery: Materials are ordered and delivered according to the specified delivery times. Quality control processes are applied in material procurement.

4. Manufacturing Process

Production Planning: A detailed plan is prepared for the production process. This plan includes the workflow, machinery, manpower, and time schedules.

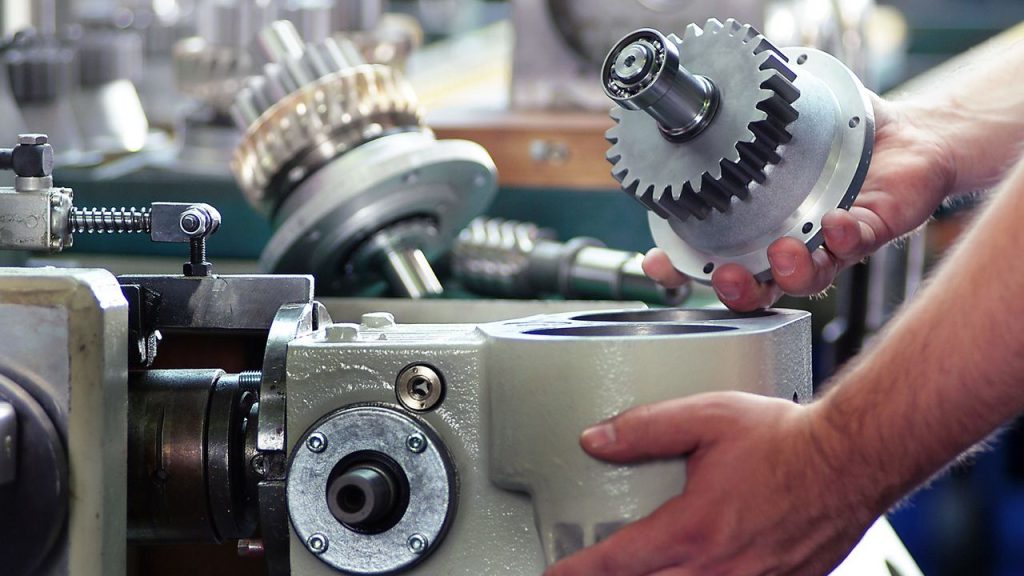

Manufacturing and Assembly: The production process is initiated, and products are manufactured. This phase includes welding, machining, assembly, and other operations.

Quality Control: Products are inspected for compliance with quality standards. This is done both during the production phase and in the final inspection.

5. Testing and Certification

Tests: Various tests are conducted to test the performance and durability of products. This includes functionality, safety and durability tests.

Certification: Certificates are obtained that the products comply with the required standards, which indicates that the products meet quality and safety standards.

6. Next Support and Maintenance

Assembly and Installation: If necessary, products are installed and assembled. This is usually provided by on-site services or technical support.

Maintenance and Support: Products are supported by maintenance and support services throughout their lifespan. This includes troubleshooting, spare parts supply and general maintenance services.

Fibaksan Machinery manufacturing and material supply process involves a series of meticulously executed steps to ensure quality, efficiency and customer satisfaction. Careful planning and execution of each stage of these processes is critical to a successful production and supply process.